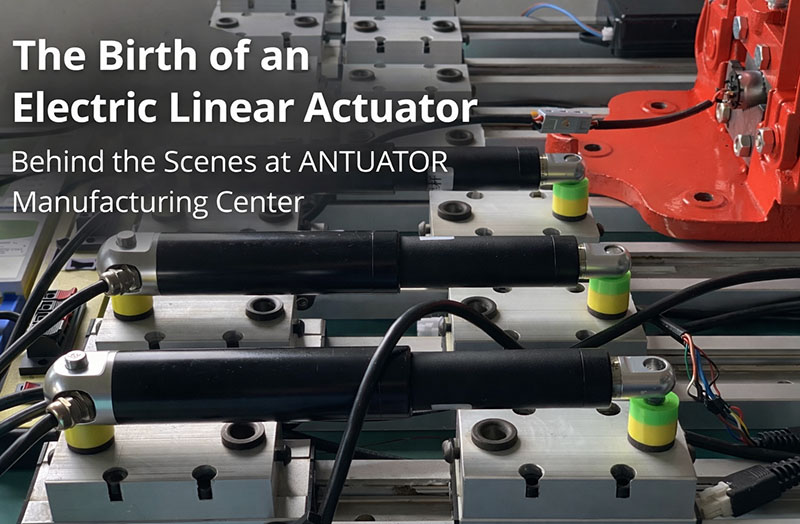

Every electric linear actuator may look compact and simple on the outside, but behind it lies a precise, systematic manufacturing process. At ANTUATOR, we believe that product quality is not inspected at the end — it is built into every step from the very beginning.

Let’s take a closer look at how a single electric linear actuator is brought to life inside the ANTUATOR production center.

Every electric linear actuator begins with a simple sentence from our customer:

“I need an actuator that can…”

Before any production starts, ANTUATOR’s sales and R&D teams work closely with the customer to fully understand the application requirements, including:

Load force and speed

Stroke length

Waterproof rating (IP67 / IP69K)

Installation method and space constraints

Operating environment (outdoor, marine, RV, sun shading systems, etc.)

Once confirmed, our engineering team converts these requirements into technical drawings, specifications, and a detailed BOM, transforming ideas into a production-ready blueprint.

This stage defines not only the function of the actuator, but also the foundation of its long-term reliability.

After order confirmation, ANTUATOR immediately enters a coordinated internal workflow:

The planning department schedules production

The warehouse checks material availability

The supply chain arranges procurement or machining

The engineering team updates ERP data

The production team prepares tooling and processes

We follow a strict principle:

“No production without complete materials.”

This ensures smooth manufacturing, stable lead times, and consistent product quality — especially critical for custom electric linear actuators.

Once production begins, every operator assembles the actuator according to process cards and technical specifications.

Key steps are recorded and self-checked in real time.

If any deviation, abnormal component, or assembly issue is detected, a rework procedure is immediately triggered — problems never pass to the next station.

Because ANTUATOR electric linear actuators are widely used in RV systems, outdoor structures, marine equipment, and sun shading applications, special attention is paid to:

Sealing structures

Waterproof performance

Mechanical durability

From the very first assembly step, reliability is designed into the product.

At ANTUATOR, quality never relies on experience alone — it is supported by systematic and verifiable testing.

All finished products, including electric linear actuators, controllers, and mounting accessories, undergo comprehensive inspections covering:

Mechanical performance

Electrical characteristics

Structural integrity

Visual appearance

Our inspection system includes:

Incoming inspection – Defective materials never enter production

In-process inspection – Key parameters checked at critical stages

Final inspection – Stroke, installation length, current, speed, and load verified

Pre-shipment inspection – Packaging, labels, and special requirements confirmed

Only products that fully meet specifications are approved for shipment.

Qualified actuators move into standardized packaging and labeling processes.

The warehouse prepares shipments according to customer requirements, while the finance department confirms payment before dispatch.

Behind every shipment is a seamless collaboration across multiple departments.

Meanwhile, ANTUATOR archives all production data and documentation, enabling:

Full traceability

Continuous process optimization

Long-term quality improvement

Electric linear actuators may be small components, but they are often used in applications where safety, stability, and reliability are critical.

At ANTUATOR:

Strict processes are our responsibility to customers

Continuous improvement is our long-term commitment

Every electric linear actuator leaving the ANTUATOR factory represents our manufacturing standards — and our promise of dependable performance.

Looking ahead, we will continue to optimize our production systems and deliver high-quality, waterproof, and application-ready electric linear actuator solutions for global customers.